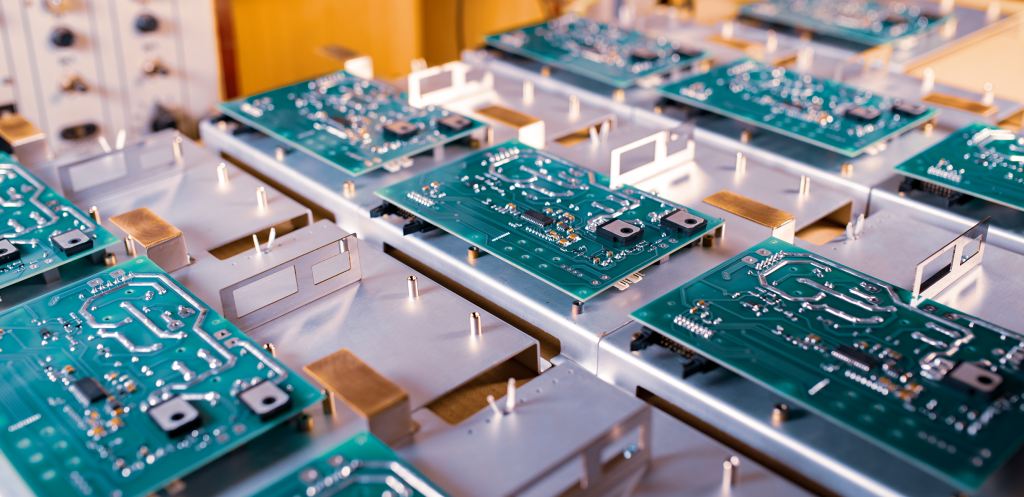

Choosing the right Electronics Manufacturing Services (EMS) partner is crucial for any Original Equipment Manufacturer (OEM) aiming to thrive in today’s competitive markets, such as consumer electronics, automotive, and industrial equipment. A reliable EMS partner not only delivers high-quality products but also ensures they reach the market swiftly and cost-effectively. Beyond technical capabilities, a valuable EMS partner offers consistent communication, growth potential, and alignment with your business goals.

Here’s a comprehensive guide to selecting the right EMS partner for your success.

1. Define Your Needs and Objectives

Start by clearly defining your product’s specific needs, such as production volume, design complexity, and desired time-to-market. Determine if you need high-volume production or low-volume, high-mix manufacturing and consider logistics advantages based on location, as a local partner may offer faster distribution and reduce lead times, while offshore partners often provide cost benefits due to economies of scale. Clarifying these needs can help you narrow down partners who specialize in your product type, enabling optimal results.

2. Prioritize Engineering Expertise in EMS Partners

An EMS partner with solid engineering expertise can support your PCB design, component selection, and custom test fixture needs. They can help solve technical challenges and reduce costs through optimized design, impacting up to 70% of manufacturing costs. Additionally, they can identify cost-saving opportunities, which is especially valuable if your company lacks in-house engineering. Review their capabilities through case studies or similar project examples to ensure they can deliver measurable cost savings and improved efficiency.

3. Evaluate EMS Technical Capabilities and Infrastructure

Ensure your prospective partner has the technical capabilities necessary for your product, including advanced manufacturing equipment, automation, and in-line testing technology. Look for advanced capabilities like Surface Mount Technology (SMT), robotic assembly, and quality testing methods. Inquire about their commitment to upgrading technology and the age of their machinery to avoid bottlenecks during production.

4. Ensure High-Quality Standards and Certifications

Your EMS provider should have rigorous quality control practices and certifications relevant to your industry, such as ISO 9001, IPC-A-610, or specific certifications like ISO 13485 (for medical devices) or IATF (for automotive). Schedule an onsite or virtual tour to review their facility, the production floor, and the quality of their equipment and workforce. These observations reflect their commitment to consistent excellence and reliability.

5. Assess Flexibility and Scalability

As your business evolves, so will your manufacturing needs. Choose a partner that offers the flexibility to scale production as needed, adapt to new products, and modify existing ones. Evaluate their capacity to accommodate growth or fluctuating order volumes without compromising quality.

6. Supply Chain Management and Logistics Support

An efficient supply chain is essential for timely product delivery and cost management. A strong EMS partner should have established supply chain networks and logistics expertise to mitigate delays and reduce costs. Examine their sourcing and inventory management practices, and ensure they have strong supplier relationships and contingency plans to address potential disruptions. This ensures they can minimize delays, lower lead times, and deliver products on schedule.

7. Evaluate Pricing with Long-Term Value in Mind

When comparing costs, it’s essential to prioritize long-term value over mere affordability. Providers with lower prices may compromise on quality or introduce delays that harm your brand. Ensure transparency in pricing, including any potential hidden fees, and verify that your EMS partner has solid supplier relationships that can lead to savings on high-demand components, allowing them to stay competitive without sacrificing quality.

8. Prioritize Communication and Collaboration

Good communication and collaboration are critical to a successful manufacturing partnership. Choose a partner that values transparent, regular updates and incorporates your input. They should be highly responsive, especially during New Product Introduction (NPI) phases. A communicative partner can help prevent misunderstandings, address issues quickly, and keep your project on track. This relationship should feel like an extension of your team, working towards mutual success.

9. Consider Localization Benefits

Localization offers strategic advantages, especially with India’s “Make in India” and “Aatmanirbhar Bharat” initiatives. If your customer base or supply chain is primarily regional, a local EMS partner can reduce lead times and logistics costs. Working with local EMS providers ensures a faster turnaround and consistent quality standards, which provides a competitive edge.

10. Assess Environmental and Social Responsibility

Today’s consumers increasingly prefer brands that demonstrate environmental and social responsibility. Select EMS partners who practice sustainable sourcing, waste management, and energy conservation. Many providers now follow regenerative practices and local environmental laws, which align with eco-conscious values and improve your brand appeal in eco-focused markets.

Conclusion

Selecting the right EMS partner requires thorough research and a deep understanding of your business needs. From technical skills to communication style, every aspect is vital in shaping a successful partnership. By following these guidelines, you’ll be well-prepared to choose a manufacturing partner that drives your product success.

-

-

-

-

PRODUCTS Transaction ProductsTrack & Trace ProductsSecurity & SurveillanceComprehensive Retail Solution (CORE) AIDC Solutions OneBox Solutions Spares OEM Models

-

-

-

-

-

-

-

-

PRODUCTS Transaction ProductsTrack & Trace ProductsSecurity & SurveillanceComprehensive Retail Solution (CORE) AIDC Solutions OneBox Solutions Spares OEM Models

-

-

-

-

Papa's freezeria

December 20, 2024 at 2:22 pmThank you! Continue to rock out.

bitlife

February 19, 2025 at 9:30 amGreat insights on choosing the right EMS provider! Clear focus on quality, scalability, and supply chain management—essential for OEMs making informed decisions.

wink mod apk

March 19, 2025 at 2:42 pmWink Mod APK typically refers to a modified (MOD) version of the Wink app, which could be a social networking, streaming, or chatting platform, depending on the original app’s purpose. A MOD APK is an unofficially altered version of an app, often providing additional features like:

Unlocked premium features (free access to paid content)

No ads (ad-free experience)

Unlimited coins, gems, or in-app currency

Enhanced functionalities (extra filters, effects, or tools not available in the standard version)

However, downloading and using MOD APKs comes with risks, such as:

Security threats (viruses, malware, or data theft)

Account bans (many services detect and block modded apps)

Legal issues (modding violates app store policies and copyright laws)

If you’re looking for specific features of the Wink Mod APK, let me know what you need!

dordle

March 31, 2025 at 1:59 pmThat is a very interesting and practical tidbit of knowledge. I cannot express how grateful I am that you just provided us with this valuable information. Please keep us updated like this. I am grateful that you shared.

sprunki retake

April 2, 2025 at 12:25 pmTakw a pen and paper a free afternoon, to analyze, rationalize.