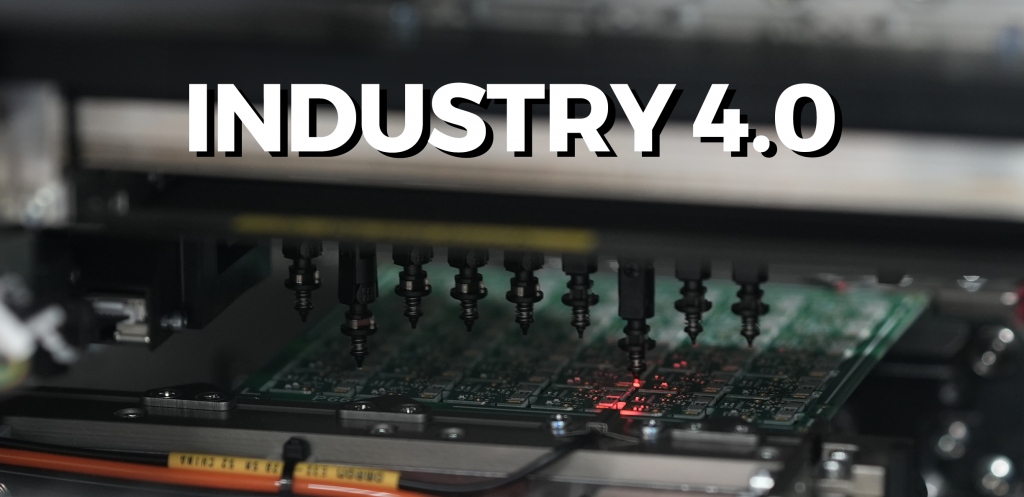

In today’s dynamic landscape, Industry 4.0 is revolutionizing electronics manufacturing with automation, robotics, AI, and the Internet of Things (IoT). This digital transformation drives efficiency, precision, and adaptability in electronics production. By integrating these technologies, electronics manufacturers achieve higher productivity, reduced costs, and enhanced quality control—essential advantages in an increasingly competitive market.

Understanding Industry 4.0 and Its Impact on Electronics Manufacturing

Industry 4.0, often called the fourth industrial revolution, builds upon previous advancements in mechanization, electrification, and early automation. Now driven by digital technologies like IoT, big data, Artificial Intelligence (AI), Machine Learning (ML), robotics, and cloud computing, Industry 4.0 creates a highly connected, automated ecosystem. For electronics manufacturing, this transformation means real-time monitoring, precision control, and significantly optimized production processes.

Key Roles of Automation and Technology in Industry 4.0

Automation is a cornerstone of Industry 4.0, converting traditional assembly lines into smart, interconnected systems. Electronics manufacturing often requires intricate tasks such as component placement on circuit boards, testing, and final assembly. Here’s how Industry 4.0 and automation are driving positive changes:

1. Enhanced Precision and Quality Control

Automated systems using AI and machine vision offer meticulous quality control. In PCB assembly (PCBA), automated optical inspection (AOI) detects defects with remarkable accuracy, ensuring only high-quality boards progress in production. This reduces human error, minimizes waste, and maintains superior quality standards.

2 . Increased Production Speed and Efficiency

Robots and AI-powered machines perform repetitive tasks faster and more accurately than human operators, drastically increasing production speed. Automated pick-and-place machines in PCBmanufacturing can place thousands of components per hour, delivering unmatched efficiency and scalability.

3. Smart Data Collection and Real-Time Analytics

A primary advantage of Industry 4.0 is the collection and analysis of real-time data from IoT sensors on machines. Electronics manufacturers can monitor energy usage, machine uptime, and output, enabling predictive maintenance that prevents unexpected downtime and optimizes resource use.

4. Predictive Maintenance and Reduced Downtime

Predictive maintenance powered by AI minimizes downtime by identifying potential issues before they lead to equipment failure. This proactive approach extends machine life, ensures uninterrupted production, and boosts operational reliability.

5. Flexible and Customizable Production

With rising consumer demand for customized electronics, manufacturers are turning to flexible production methods. Automated systems in an Industry 4.0 environment quickly adjust to product variations, enabling “mass customization” without efficiency losses.

6. Improved Traceability and Compliance

Industry 4.0 simplifies traceability across the entire production chain, from raw materials to final assembly. Traceability is crucial for quality control and compliance in electronics manufacturing, allowing manufacturers to quickly address and resolve issues, thus upholding high standards.

Real-World Applications and Smart Manufacturing Systems

Electronics companies are already leveraging advanced Industry 4.0 solutions to optimize production. For instance, Surface Mount Technology (SMT) lines enhanced by IoT enable precise component placement, quality checks, and streamlined processes. At TVS Electronics, our Manufacturing Execution System (MES) integrates advanced control systems, enabling real-time monitoring of production, resource allocation, and equipment efficiency, creating a responsive and agile manufacturing setup.

Future Trends: The Evolution of Industry 4.0 in Electronics Manufacturing

Emerging trends in Industry 4.0 for electronics manufacturing include AI-driven predictive systems that reduce downtime, 5G and edge computing for faster data transmission, and digital twins that simulate production processes. These advancements will enable manufacturers to optimize efficiency, boost innovation, and stay competitive in a rapidly changing market.

Conclusion: Embracing Industry 4.0 for Competitive Advantage

The transformative impact of Industry 4.0 is more than just a trend; it’s essential for electronics manufacturers aiming to stay competitive in the global market. By adopting automation and Industry 4.0 solutions, manufacturers improve precision, flexibility, quality, and speed to meet modern demands.

To learn more about how TVS Electronics can integrate Industry 4.0 technologies into your manufacturing process, contact us today. Together, we can shape the future of electronics manufacturing.

-

-

-

-

PRODUCTS Transaction ProductsTrack & Trace ProductsSecurity & SurveillanceComprehensive Retail Solution (CORE) AIDC Solutions OneBox Solutions Spares OEM Models

-

-

-

-

snow rider

March 6, 2025 at 8:50 amIndustry 4.0 is transforming electronics manufacturing with automation and AI, boosting efficiency and precision.

Rodha

March 16, 2025 at 3:15 pmRodha:Rodha-2D Platform Adventure with 60 Challenging Levels

Block Breaker

March 16, 2025 at 3:22 pmPlay Block Breaker online free! Experience classic Block Breaker, Block Breaker 3D, and Deluxe versions.

ことのはたんご

March 16, 2025 at 3:22 pmことのはたんご – 日本語版 Wordle。言葉で遊ぼう!毎日挑戦する単語パズルで、日本語の楽しさを体験しよう。

Retro Bowl

March 26, 2025 at 12:07 pmDesigned to coach your squad and earn a trophy at the end of every season, Retro Bowl is an American football game with retro flair.

alight motion

March 27, 2025 at 2:53 pmFrom motion graphics to color effects, Alight Motion has everything you need.

redactle game

March 31, 2025 at 2:03 pmFantastic blog. It was interesting to read your article. This is a great, fascinating website, in my opinion. I would love to read more from it and have bookmarked it. Keep up the fantastic work!

myfiosgateway

April 13, 2025 at 12:17 amIn a tech-forward era like Industry 4.0, having a reliable home network setup with a smart router interface makes it easier to manage connected devices and stay ahead in a fully digital environment.