The Rise of Make in India: Transforming the EMS Landscape

The impact of Make in India on manufacturing has been profound, particularly in the Indian electronics manufacturing sector. This initiative has reshaped the Electronics Manufacturing Services (EMS) industry by fostering growth, innovation, and self-reliance in the Indian economy. With government policies for EMS in India, increasing investments, and a focus on localization, the initiative is driving a paradigm shift in electronics manufacturing. This transformative movement positions India as a global manufacturing hub while meeting the growing domestic demand for high-quality, cost-effective electronic products.

Understanding the Make in India Initiative and Its Impact on EMS

Launched in 2014, the “Make in India” program aims to promote indigenous manufacturing across sectors, including electronics. With a focus on reducing imports, boosting exports, and creating jobs, the initiative has brought strategic policy reforms and infrastructure development to support the EMS industry.

For EMS providers, this transformation means new opportunities in component manufacturing, assembly, and the production of finished electronics. The push for localization, coupled with global supply chain disruptions, has further accelerated India’s EMS growth trajectory.

Key Drivers of EMS Growth Under Make in India

- Government Incentives and Policies

The Indian government has introduced various schemes to strengthen the EMS industry growth, notably:

- Production Linked Incentive (PLI):Offers financial incentives to manufacturers meeting production and investment targets, boosting competitiveness and export potential.

- Electronics Manufacturing Clusters (EMC):Supports the development of dedicated EMS hubs, providing necessary infrastructure and resources for manufacturers to scale operations.

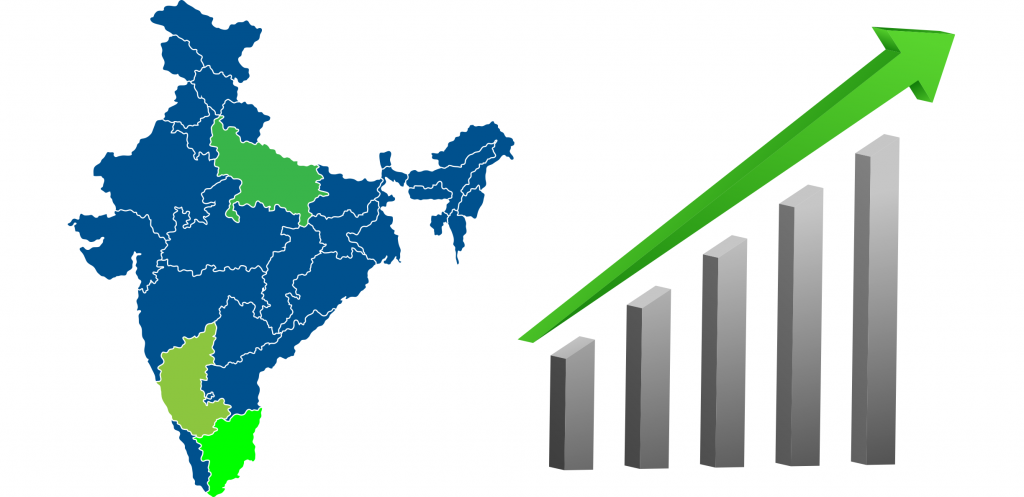

- Rising Investments in EMS Infrastructure

With domestic and international companies investing heavily in manufacturing facilities, states like Tamil Nadu, Karnataka, and Uttar Pradesh are emerging as key EMS hubs. These investments create a robust ecosystem for electronics production, encouraging collaboration between component suppliers and manufacturers.

- Focus on Import Substitution

India has historically relied on imported electronic components. The Make in India initiative emphasizes import substitution, encouraging EMS partners to establish local supply chains for components such as PCBs, semiconductors, and displays. This shift reduces dependency on foreign suppliers and enhances supply chain resilience.

- Growth in Consumer Electronics and IoT Demand

The surge in demand for consumer electronics, IoT devices, and smartphones in India provides a lucrative market for EMS providers. Companies are increasingly partnering with local manufacturers to cater to this growing market, aligning with Make in India goals.

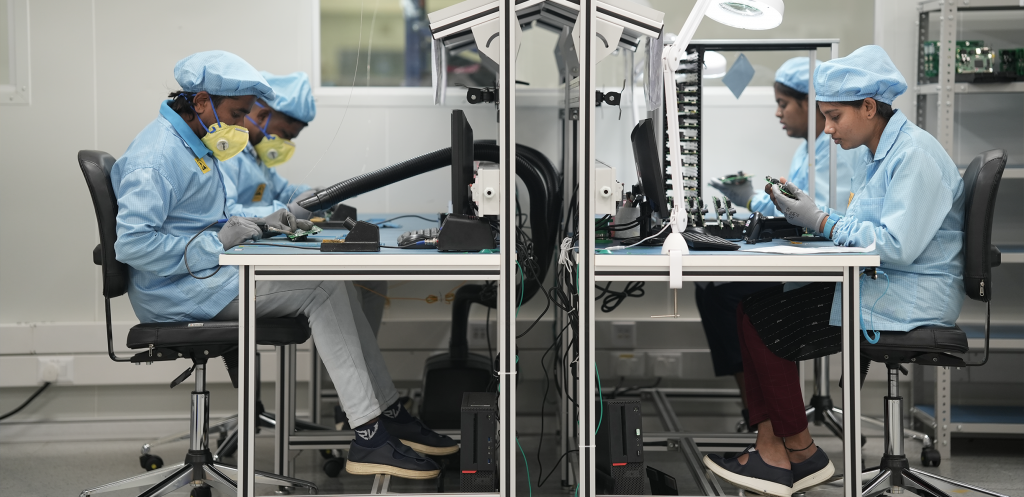

- Job Creation and Skill Development

Workforce development is a critical pillar of Make in India. Programs under Skill India and partnerships with educational institutions aim to bridge the skills gap, enabling a competitive workforce for advanced manufacturing.

Future Trends and Opportunities in Make in India for EMS

The future of EMS in India is promising, with several emerging trends set to drive further growth:

- Semiconductor Manufacturing:With government initiatives promoting semiconductor fabrication, India is on its way to reducing reliance on imported chips.

- Green Manufacturing Practices:Sustainable manufacturing is gaining traction, as EMS providers adopt eco-friendly manufacturing solutions that align with global standards.

- AI and Automation in EMS:Advanced technologies integrate AI and automation is streamlines manufacturing processes, improves efficiency, and ensures scalability.

The Road Ahead for EMS Under Make in India

The Make in India initiative has established a strong foundation for the EMS industry to thrive. By fostering technological advancements, promoting self-reliance, and reducing import dependency, it has positioned India as a competitive player in the global electronics manufacturing space. EMS providers that align with this vision stand to gain significantly, contributing to India’s economic growth while reinforcing their leadership in the industry.

Contact us today to learn how TVS Electronics can support your business under the Make in India initiative. Together, let’s shape the future of electronics manufacturing in India.

-

-

-

-

PRODUCTS Transaction ProductsTrack & Trace ProductsSecurity & SurveillanceComprehensive Retail Solution (CORE) AIDC Solutions OneBox Solutions Spares OEM Models

-

-

-

-

-

-

-

-

PRODUCTS Transaction ProductsTrack & Trace ProductsSecurity & SurveillanceComprehensive Retail Solution (CORE) AIDC Solutions OneBox Solutions Spares OEM Models

-

-

-

-

INP Technologies

February 19, 2025 at 3:16 pmThe Make in India initiative has significantly transformed the Indian EMS industry, promoting self-reliance and fostering growth through government support, infrastructure development, and increased investments. With a focus on localization and reducing import dependency, India is emerging as a key global player in electronics manufacturing. The growing demand for consumer electronics and IoT devices, coupled with innovations like semiconductor manufacturing and AI-driven automation, offers promising opportunities for the future. This shift not only boosts the economy but also creates a robust ecosystem for local manufacturers. Exciting times lie ahead for India’s EMS sector!

how much is kinemaster pro

May 24, 2025 at 12:45 pmAdvanced Editing, Simplified – KineMaster Pro.

Stickman Hook

March 13, 2025 at 1:48 pmI like this post

fireboy and watergirl

March 31, 2025 at 2:10 pmIt’s a very pleasant and helpful bit of knowledge. I’m happy you gave us this important information. Keep us updated in this manner, please.I appreciate you sharing.

geometry dash meltdown

April 2, 2025 at 2:38 pmThe information was excellent and provided me with a new perspective on the subject; I am pleased to have contributed so much new knowledge to this sector.

happymod

April 8, 2025 at 11:07 amHappyMod is a powerful tool for Android users who want to get the most out of their apps and games.

hdstreamzs

April 12, 2025 at 10:48 pmHD Streamz APK has carved a niche for itself as a go-to solution for those looking to access live TV, radio, movies, and shows from across the globe—all in one place.

ucbrowsertool App

April 14, 2025 at 10:13 amUC Browser APK is a popular Android-based web browser that stands out for its speed, data-saving technology, and user-friendly interface.

ressomodapk

April 15, 2025 at 12:25 amRessomodapk has emerged as a reliable platform offering safe and optimized modded APKs to Android users across the globe.

connections solver

April 20, 2025 at 11:31 amThank you for sharing. I also have something to share that I would like to tell you Welcome to the definitive NYT Connections solver tools word connections solver , puzzle enthusiasts!

Snow Rider 3D

April 22, 2025 at 9:00 amMake in India is revamping electronics manufacturing services! Imagine navigating complex supply chains like the challenging slopes of Snow Rider 3D. Government initiatives and rising investments are fueling growth. This localization push lets EMS providers manufacture components and assemble finished electronics. India’s aiming to be a global manufacturing hub, offering high-quality, cost-effective electronic products.

kinemaster APP

May 21, 2025 at 12:07 pmKineMaster Mod APK has emerged as a popular choice among content creators, especially those looking for professional features on mobile without the limitations of the free version.

nulls brawl pro apk

May 21, 2025 at 12:26 pmNulls Brawl APK stands out as an entertaining and flexible option for fans of Brawl Stars. Whether you’re looking to test all brawlers, enjoy exclusive skins,

picassotv

May 23, 2025 at 10:53 amPicassoTV stands out as a free, high-quality streaming service that offers a vast array of content. Whether you’re a movie buff, a sports enthusiast, or someone who enjoys binge-watching the latest TV shows, PicassoTV caters to all your entertainment needs.

picassotv

May 23, 2025 at 10:56 amPicassoTV stands out as a free, high-quality streaming service that offers a vast array of content. Whether you’re a movie buff, a sports enthusiast, or someone who enjoys binge-watching the latest TV shows, PicassoTV caters to all your entertainment needs.

spotify mod apk

May 23, 2025 at 3:05 pmSpotify Mod APK may seem attractive to those looking for premium features at no cost. However, the risks and ethical implications outweigh the temporary benefits. Supporting artists and enjoying music legally not only ensures a secure user experience but also helps sustain the music industry.